Torbo Machines

There is no limitation on the application areas!

All Torbo Units can be manufactured with ATEX Certification!

Softline XS - S

The SoftLine machines are the smallest devices for the simple, effective and gentle cleaning of monuments and facades. They don’t need an extra air dryer, no extra water hose to the nozzle and no heavy or expensive nozzle. Thanks to the control system, the blasting media mixture (80% blasting abrasive and 20% water) and extra water is metered out irrespective of compressed air, so that you can adjust the parameters independently of each other.

Technical data:

| SoftLine XS | SoftLine S | ||

| Vessel size | l (dm³) / Cu. ft. | 50 l | |

| Control pressure | bar / PSI | 12/ 170 | |

| Weight (empty) | kg / Ibs. |

115 -130 / 250 - 290 |

|

| Dimensions (h x w x d) approx. | mm inch |

990 x 570 x 520 / 39 x 22 x 20 |

|

| Size air connection | mm / inch | 13 / 1/2 | 19 / 3/4 |

| Air connection (min. - max.) | m³/min Cu ft. per min. bar PSI |

1,5 - 2,8 53 - 99 4,0 - 10,0 58 - 147 |

2,2 - 4,0 78 - 142 4,0 - 10,0 58 - 147 |

| Connected power | Volt / Watt | 12 / 4 | |

| Water connection (min. - max.) | bar PSI |

0,2 -12,0 0 - 170 |

|

| Blasting hose connection | mm / inch | 19 / 3/4 | |

| Standard blasting mixture | abrasive/water | 80% / 20% | |

| Average blasting time per filling | Std. (h) | 1,0 | |

| Blasting time (100% period of use) | Std. (h) | 3,12 - 0,31 | |

| Consumption of blasting media | l/min / gpm (US) | 0,24 - 2,40 / 0,06 - 0,63 | |

|

Water consumption during blasting |

l/min / gpm (US) | 0,06 - 0,60 / 0,02 - 0,16 | |

M - L

The M-version has been specially developed for gentle work, also cleans delicate surfaces thoroughly and leaves even brilliant results when other blasting devices have to give up a long time ago. The cleaning of facades, sandstone monuments, the use during restoration work or the removal of graffiti are just as much to its range of applications such as the careful historic preservation with receipt of the patina or the rays of ornaments on glass.

The specialty of the L-version is its diverse range of uses. The specially developed for the all-round demand system is characterized in daily use. The gentle removal of even stubborn encrustations of sensitive surfaces is just as much to its range of applications such as the removal of concrete slurry and layers of paint, or the use of fire restoration.

Technical data:

| torbo M | torbo L | |||

| Vessel size | 80 l. (120 l.) | 120 l. (240 l.) | ||

| Water tank | —- | |||

| Hose reels | —- | |||

| Compressor | —- | |||

| Blasting media consumption (min-max) | 14,4 to 144 (288) l/h (depending on the metering / setting) | |||

| Water consumption (min-max) | 3,6 to 36 (72) l/h | |||

| Compressed-air connection (min-max) | 2 - 6 m³/min 4 - 10 bar |

3 - 10 m³/min 4 - 10 bar |

||

| Water connection (min-max) | 0 - 12 bar | 0 - 12 bar | ||

| Blasting hose connection | 25 mm / 1 inch | 38 mm / 1 1/2 inch | ||

| Power supply | 12 volt / 3 watt | |||

| Dimensions (LxWxH), approx. | 720 (830) x 660 x 1.130 (1.220) mm | 720 (830) x 660 x 1.130 (1.220) mm | ||

| Unladen weight, approx. | 120 - 175 kg | 125 - 180 kg | ||

| Perm. total weight | 350 kg | 500 kg | ||

XL

Devices of this class are characterized by a large vessel volume and therefore they only need 1 to 4 vessel fills in a day.

The XL-version has plenty of power for any remedial measure. The torbo system shows its strength with heavy inserts. With ease it cope the removal of concrete slurry, the removal of old paint and the deburring and descaling of metals, as well as the removal of oxidation layers on steel.

Technical data:

| torbo XL | ||

| Boiler size | 240 l. (320 l.) | |

| Water tank | —- | |

| Hose reels | —- | |

| Compressor | —- | |

| Blasting media consumption (min-max) | 14,4 to 288 (XL-S: 576) l/h (depending on the metering / setting) | |

| Water consumption (min-max) | 3,6 to 72 (XL-S: 144) l/h | |

| Compressed-air connection (min-max) | 4 - 15 m³/min 4 - 10 bar |

|

| Water connection (min-max) | 0 - 12 bar | |

| Blasting hose connection | 49 mm / 2 inch | |

| Power supply | 12 volt / 3 (9) watt | |

| Dimensions (LxWxH), ca. | 1.100 x 750 x 1.360 mm (1.260 x 750 x 1.490 mm) | |

| Tade weight, ca. | 220 - 300 kg (245 - 320 kg) | |

| Perm. total weight | 900 kg (1.100 kg) | |

TorboCar AC

Abrasive wet blasting units built in trailer with integrated compressor. Various models with capacity from 80 to 320 lt. These units are convenient to work and transportation.

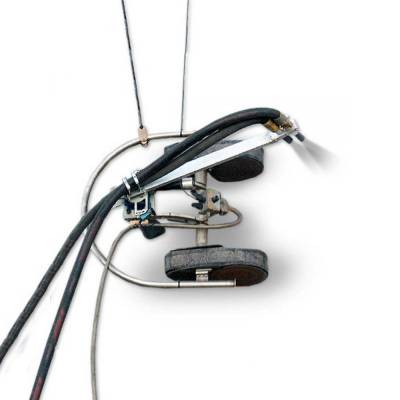

Mate Crawler

Robot for vertical and horizontal surfaces. High cleaning efficiency with safety for the users because there is no need for scaffolding. The robot is remote controlled.

Special Selection

Torbo according to your wishes...

Whether it be an orange SoftLine or maybe a torbo XL in red: We offer our machines in your colors. No matter if it is the color of your company or your community. In general all colors are available from the RAL color chart. Talk to us and we will help you in designing your own personal torbo!

But we not only fulfill your wishes of coloring. A fixed installation (torbo unit plus compressor) on your service vehicle or a redesigned your needs torbo machine, we would like to make your dreams come true. So it is no problem to make a torbocar which is equipped with two torbo machines.

Or maybe you like one of our existing special purpose machines, such as the torbo N-LOC. Especially when cleaning facades and monuments the N-LOC characterized by its ease of use, low weight and built-in water tank. In its aluminum frame (with removable wheels) and its retractable handles it is portable and easy to transport.

We realize your dreams in the area of what is technically feasible. Please contact us, we will advise you.

ATEX Machines

Abrasive wet blasting units with ATEX certificate, for use in explosive areas. Ideal units for work in refineries, petrochemical, oil platforms, gas pipelines, LNG tankers, chemical industry and tanker vessels.